| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Aquatrin

Model Number : XGF24-24-8

Certification : ISO CE

Place of Origin : Jiangsu, China

MOQ : 1unit

Price : USD15000-60000 1Set

Payment Terms : T/T

Supply Ability : 10units per month

Delivery Time : 45days

Packaging Details : wooden package

Processing Types : Automatic Bottle Filling Sealing Machine

Air comsumption : 0.8M3/ min

Filling material : Flowing Liquid

Bottle type : PET Plastic Bottle or glass bottle

Dimension(L*W*H) : 3000*2200*2800mm

Applicable Industries : Manufacturing Plant, Food & Beverage Factory

Hot Sale Drinking Water Filling Machine With Good Quality

PET bottled filling machine with capacity from 2000BPH to 36000BPH. This kind of packing features light, good-tenacity, strong-intensity and hard-breakage, in addition, PET bottle can be made into different specs and shapes; For the consumer, they can take easily and conveniently without exploding.

Features:

1. This filling water machine is a unique design combining the three machines of bottle washing, filling and capping in one to decrease main power, to save space and to diminish the air pollution among the three machines.

2. The machine is easy to change the shape of bottles, which can be done by changing thethumb wheel without adjusting the height of the machine.

3. The filling water machine case and the parts contacting with the materials are made ofstainless steel which ensures the good external look and easy washing.

4. Each water filling machine element tha contacts with the liquid is made of high quality Stainless steel 304, if needed,Stainless steel is also available.

5. The water filling machine adopts bottle neck holding transmission technology to realize fully automatic rinsing, filling and capping.

6. Most elements of the electrical system use famous international brand, for example, Mitsubish, Omron brand .

7. The water filling machine obtain the advantages of good abrasive resistance,high stability,low failure rate, etc. The quality of the equipments reaches the advanced level of the world.

8. Nozzles in the grab can guarantee the complete wash of the interior of the bottle.

9. Easy to operate, save the cost for workers.

Main Parameters:

| Model | CGF12-12-4 | CGF18-18-6 | CGF24-24-8 | CGF32-32-10 |

| Capacity | 3000-4000BPH | 5000-6000BPH | 8000-10000BPH | 10000-14000BPH |

| Applicable bottle | Plastic bottle 500ml-1.5L Plastic screw cap

| |||

| Applicable filling content | Mineral water, wine, non-carbonated water | |||

| Washing station | 12 | 18 | 24 | 32 |

| Filling nozzle | 12 | 18 | 24 | 32 |

| Capping head | 4 | 6 | 8 | 10 |

| Main motor power | 2.2kw | 2.5kw | ||

| Water pump power | 0.37kw | |||

| Dimension (mm) | 2350*1850*2450 | 2700*2100*2450 | 2800*2400*2450 | 3200*2800*2450 |

| Weight (kg) | 3500 | 4500 | 5500 | 6800 |

Production Line Flow

Drinking Water Treatment Equipment

Process: Spring-raw water booster pump, mechanical filter, precision filter, active carbon filter, sodium exchanger, RO machine/ hollow fiber ultrafiltration device, Store tank, UV sterilizer, ozone generator and other equipment.

It can effectively get rid of muddy organic, iron, manganese and oxide, filter suspended substance, colloid, remained oxygen of micro-organism and some of height-metal ion in the water. This water treatment equipment can also reduce hardness of water to make it all specifications of the water quality fully meet the state fresh water standards, even that of standard of mineral water,

Bottle Blowing Machine

Automatic PET Bottle Blowing Machine is suitable for blowing PET bottles of various shapes, volume from 100 ml to 2000 ml, wide application for blowing mineral water bottles, soda bottles,cola bottles.

Advantages

1.New double crank four pull-up bar clamping structure, cross balance fixed slide.

2.Sealing, stretch adapts parallel bars (CIS) design, combined, good for products molding.

3.Advanced gas path design, single, dual air intake can be; low-pressure mechanical clamping, sealing, stretching; high pressure blowing molding.

4.Programmable PLC controller automatically control, microcomputer touch screen convenient operation.

5.Bottle embryo heated by infrared, controllable constant pressure control, so as to achieve the best blowing precision.

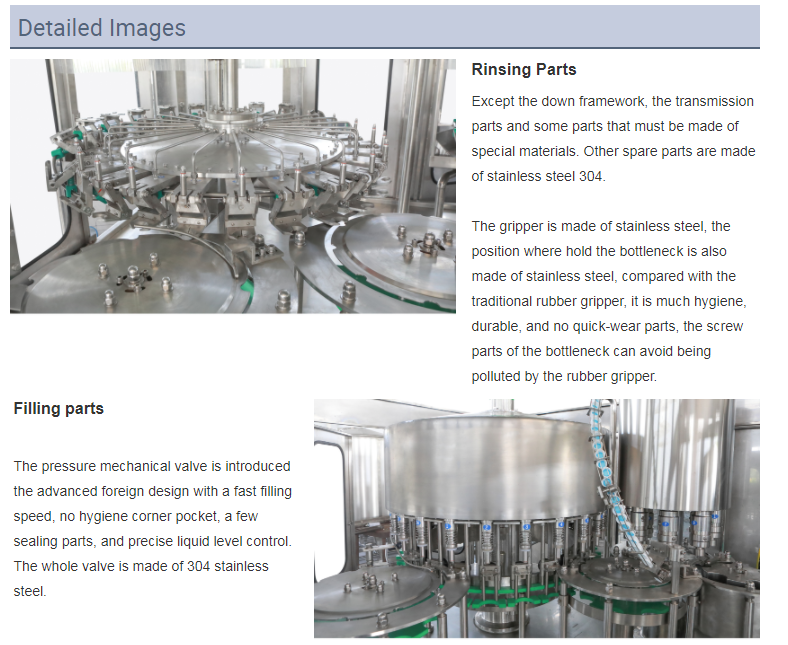

Washing, Filling, Capping 3-in-1 Machine For Filling Water

Washing, Filling, Capping 3-in-1 Machine is a set of equipment with high precision and speed to fill liquid. It adopts bottle-neck block technology, not only avoiding second pollution to the bottle-neck, but also realizing filling different specs of bottles in one equipment, which greatly improved commonality of this equipment. Production capacity is 2000 bottles to 250000 bottles per hour. Main-frame machine adopts frequency controlling electric motor, which is much convenient to adjust speed in scope of production capacity.

| Model: | XGF 24-24-8 |

| Capacity:500ml(b/h) | 14000 |

| Suitable Bottle:(mm) | 150-340 |

| Suitable Cap: | Diam50-110 (mm) |

| Filling Pressure(Mpa): | 0.2-0.3 |

| Power: (KW) | 5 |

| Filling Temperature: | Indoor Temperature |

| Size: L×W×H (mm) | 2750×2180×2200 |

| Total Weight:(kg) | 4000 |

|

|

2.5kw 0.8M3/ Min Drinking Water Filling Machine 36000BPH Images |